V-belts, elastic and timing belts: what they are and how they work

When people talk about industrial sewing machines, they immediately think of needles, motors, presser feet and speed. But there is one component that works silently and ensures that everything runs smoothly: the drive belt. It is she who transfers power from the motor to the sewing mechanism, ensuring that every stitch is executed with precision.

In this article we look at how belts work, why there are different models, and how to choose the right one for your industrial machine.

The cure of

Andrea Ferroli

Nadia Leonarduzzi

Drive belts: what they are and what they are used for

Drive belts are flexible mechanical components that connect two rotating parts (usually a drive pulley and a drive shaft), transmitting motion in a continuous and regular manner.

In industrial sewing machines, the belt serves to synchronize the various internal mechanisms, such as needle, shuttle and fabric transport. An efficient belt ensures

- fluidity of movement

- stitch precision

- less wear and tear on components;

- less noise and vibration.

It is therefore important to know which belt is the most suitable, when to replace it and what advantages each type offers.

Because there are different types of belts

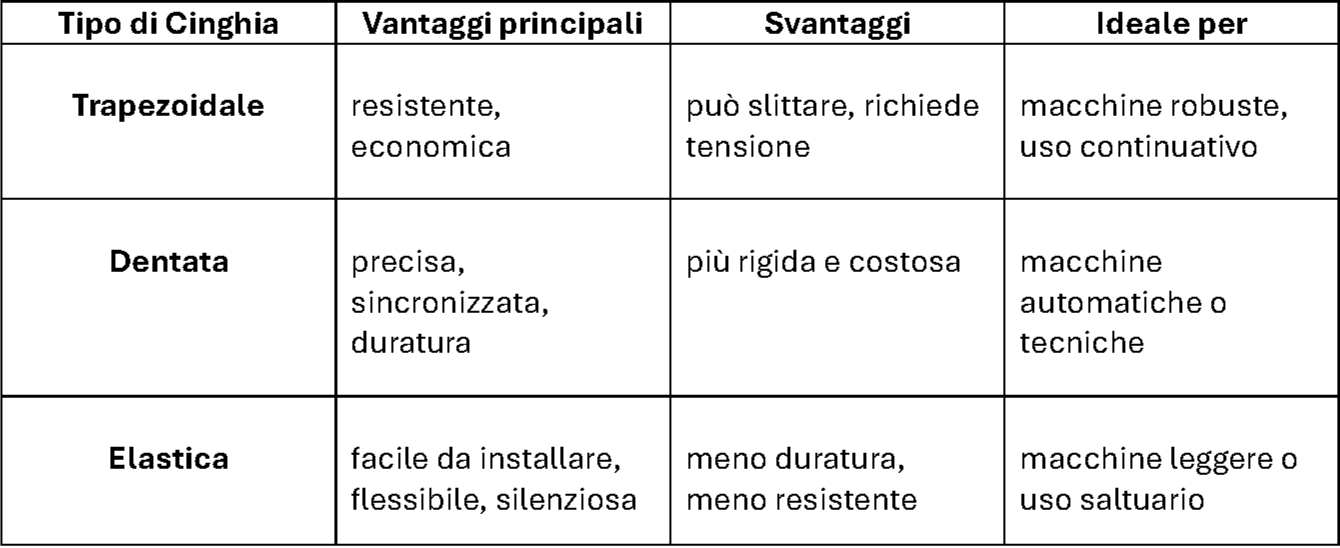

Each machine has different characteristics: the main variables are weight, frequency of use, speed and the ideal type of machining. The mechanical requirements change accordingly, and with them the belts to be used. This is why there are several types, each with specific functions.

Let us look at three of the most commonly used: V-belts, timing belts and elastic belts.

V-belts: features and advantages

V-belts are one of the most commonly used belts in mechanical transmissions. They have a trapezoidal section that fits into the pulley grooves, ensuring a stable, slip-free drive. They are ideal for robust and heavy-duty sewing machines.

They have several advantages:

- good grip

- resistance to high loads;

- easy availability.

But they also have disadvantages:

- they can stretch with use;

- require regular tensioning.

Timing belts: features and advantages

Timing belts are recognized by their characteristic internal “teeth” that fit precisely onto the grooved pulleys. This makes them perfect for synchronous drives, where precise movement to the millimeter is essential. They are ideal for automatic or technical sewing machines.

Here are their main advantages:

- slip-free transmission

- Perfect synchronization;

- superior durability.

And these are the main disadvantages:

- stiffer than the others;

- require compatible pulleys.

Elastic belts: features and advantages

As the name suggests, elastic belts offer flexibility and adaptability. They can be mounted without disassembling the machine, because they stretch during installation. They are perfect for light or occasional use machines, where comfort and ease of use are more important than the power transmitted.

Among the main advantages are:

- ease of installation

- vibration damping;

- quieter operation.

Some disadvantages may be:

- belts less suitable for heavy loads;

- generally shorter service life than timing belts.

What is the right belt for your industrial sewing machine?

Choosing the ideal belt depends on several factors: the type of machining, frequency of use, the level of precision required, and ease of installation. Those who work with robust machines and need endurance may lean toward a V-belt. If, on the other hand, maximum precision is sought, such as in automatic or technical processes, a timing belt is the best choice. Finally, elastic belts are perfect.

Contact a Fitex technician: he is the perfect figure who can help you identify the most suitable solution, being able to draw on a complete catalog of belts compatible with the main industrial models.

When does a belt need to be replaced?

There are some signs that should not be underestimated to avoid machine damage.

If the machine starts to slip, if the stitching is not smooth, or if you feel abnormal vibrations, it is likely that the belt is worn. Visually, too, you may notice any cracks or signs of wear and tear, indicating that it is time to replace it.

To avoid downtime, it is advisable to perform regular checks, at least every six months. Fitex offers a full range of sewing machine spare parts and a specialized advisory service to help you choose.

Conclusion

Choosing the right belt is not just a technical matter, but a strategic decision that can improve production efficiency and reduce downtime.

Fitex stands by textile workshops and professionals by providing reliable components and tailored technical support.

Also discover our professional sewing machines

Order Directly with the Fitex App

Already know which item you need?

Order it directly from our app, available for Android and iOS.